How Are These Thermal Images Being Used To Help A Range Of Companies?

These thermal imaging devices can be uses to locate problems in a range of industries. The immediate purpose in many industries lies in fault detection. Skilled technicians that can understand these abnormal heat signatures can use their readings to aid with maintenance and repair.

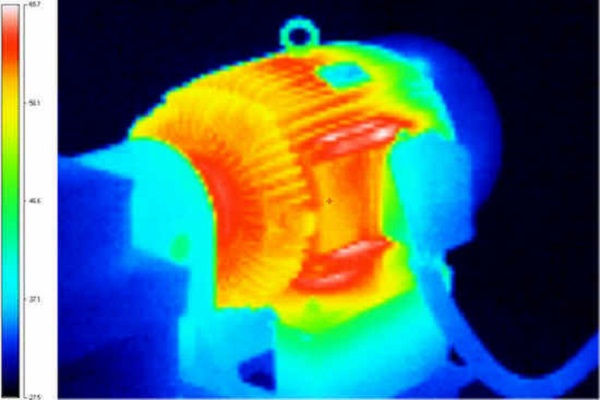

The sooner that these faults are detected, the greater the chance of a quick, cost-effective repair. Many use them for looking at the heat generated in the moving parts of rotating equipment, such as motors and their bearings. An overloaded bearing or an overheating motor could be the start of a much bigger problem.

Thermal cameras can also play an important role in other applications, including energy conservation and security. These colorful maps of heat signals allow surveyors to locate areas where heat is being lost from a building. This pinpoints areas in need of better insulation or energy conservation and can be as detailed as a small patch of air.

These surveys could save that home or business a lot of money. People also show up with these infrared thermographic cameras because of body heat. This can be useful for security footage in dark areas.

This Is A Skilled Profession That Many Industries Can Take Advantage

The best way to test for these faults is to call in an expert. All companies should locate one that has experience in the area and the ability to read fine details in these images. All inspectors also need to be certified under the applicable bodies.

These technicians will come and look at the machinery, building or area in question under normal conditions. This means a motor that is running under a normal load or an office building operating to normal standards. This helps to highlight any readings that would be considered abnormal.

It is also important that these technicians have a clear line of sight to the problem area for the best result. Finally, it is recommended that areas are re-inspected after repairs to determine the difference made and that inspections take place annually.

Thermography is an important science. It should not be overlooked by companies that want to protect their equipment and better understand its function. Any company concerned about the health and safety of their equipment, or the energy efficiency of the building, should contact a specialist.

Annual inspection and regular checks on repairs may seem like a hassle when there is no immediate issue. However, they can save a lot of time, money and effort down the line. It is best to find a small issue that is easily fixed than a big invisible problem.