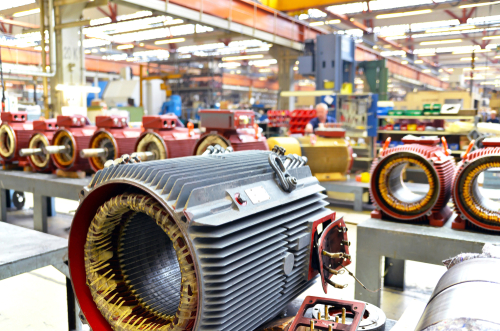

Types of Electric Motor Options Available For Different Applications

Electric motors were created in the late 1800s. By 1887, the electric motor was installed on the first electric trolley system in Richmond, Virginia. By 1892, the electric elevator and control system was devised. Thomas Edison promoted D.C. electricity and built electric power transmission systems to power D.C. motors.

Modernizing the Industrial Steam Age

That sparked an "industrial revolution" by enhancing industrial applications. Industrial procedures were restricted by power transmissions using straps, line shafts, compressed air, or hydraulic pressure. With the electrical motor, every machine could be powered by its own electric motor and provide easy control at the point of use: this enhanced power transmission efficiency and increased safety and ease of setting up production.